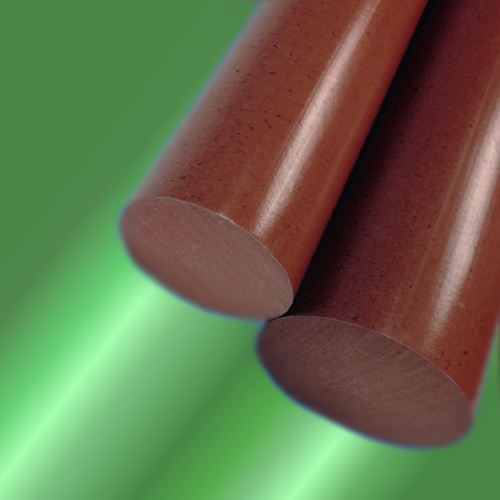

PHENOLIC FIBER ROD

PHENOL FIBER ROD

Phenol Fiber Board is produced by applying modified phenolic resin as a binder to pure cotton fabric used as a reinforcing agent. The product has excellent heat resistance and will not exhibit friction properties at high temperatures. These products are produced from cotton fabric impregnated with phenolic resin binder. The products have good mechanical properties, good heat and moisture resistance and excellent wear resistance. The mechanical strength of cotton-based products is higher than paper-based products. Phenolic resins are among the oldest and best known general-purpose thermosetting resins. In general, phenolics are not as good as epoxies in terms of moisture and moisture resistance, dimensional stability, shrinkage and permanence of electrical properties. These products contain medium-density woven canvas fabric and stand out with their mechanical properties. This class of products is not recommended for electrical insulation.

Features:

Excellent physical, mechanical and di-electrical properties

Suitable for machining with any type of machine

Excellent machinability

Mechanical and electrical properties

Usage areas:

electrical equipment

Aviation Industry

Structural part/component isolation

Engine and electrical equipment

TECHNICIAL SPECIFICATIONS

Specific Gravity 1.45 g/cm3

Tensile Strength 81~130 Mpa,1100Mpa+

Impact Strength 67 kj/m2

Water Absorption

0.12%~0.25%

Temperature Resistance(Short Time) 300℃

Temperature Resistance(Continuous) 180min*130℃

Bending Strength 170 Mpa+

Size 1000mm

Thickness Ø 10 - 200 mm