PTFE FABRIC

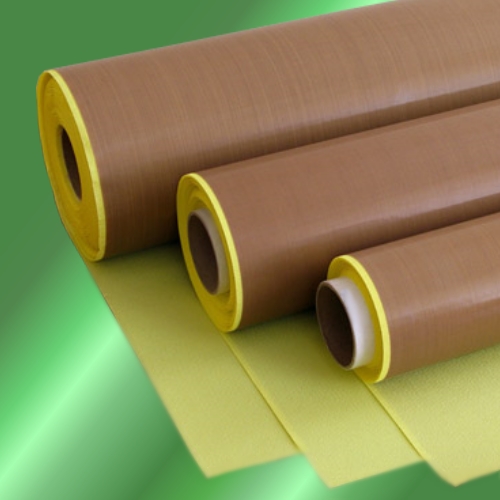

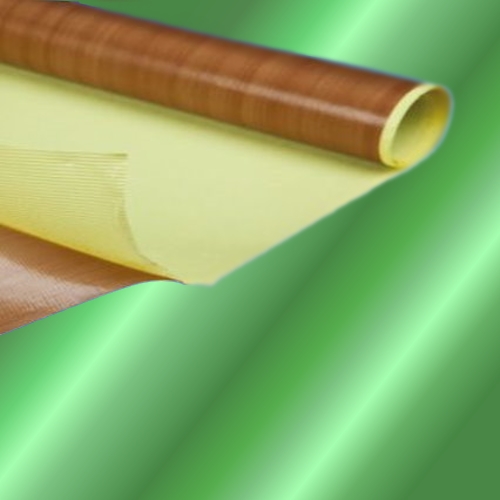

ADHESIVE PTFE FABRIC

Adhesive PTFE fabric is produced by coating a surface of PTFE coated glass fabric with a high temperature resistant silicone adhesive on this surface after a special treatment. This excellent product, which is made of high temperature resistant (–70°C to +260°C) PTFE coated glass fabric and silicone adhesive, helps to solve specific problems in many industries thanks to its easy use. Self-adhesive fabrics are produced in 1 meter width as standard, the silicone adhesive surface is covered with a yellow plastic film. Balls are usually produced in 50 m.

Adhesive PTFE coated glass fabrics are helpful in solving specific problems in high temperature processes where non-adhesion is required such as plastics, packaging, textiles, food, electronics. It is used in applications such as coating the welding jaws in packaging machines, coating the welding jaws in the corner welding machine in the production of PVC doors and windows, coating various rolls in processes where non-adhesion is required in the textile industry.

P.T.F.E. MATERIAL

PTFE coated glass fiber fabric is woven from quality E-glass filament yarns. Then, both sides were coated with PTFE by applying special processes.

Oven and microwave drying movable belts are an excellent and ideal material for welding blankets, fire protection curtains, expansion joint equipment, non-metallic compensators and corrosion prevention applications.